| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vacuum Pyrolysis Cleaning Device | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

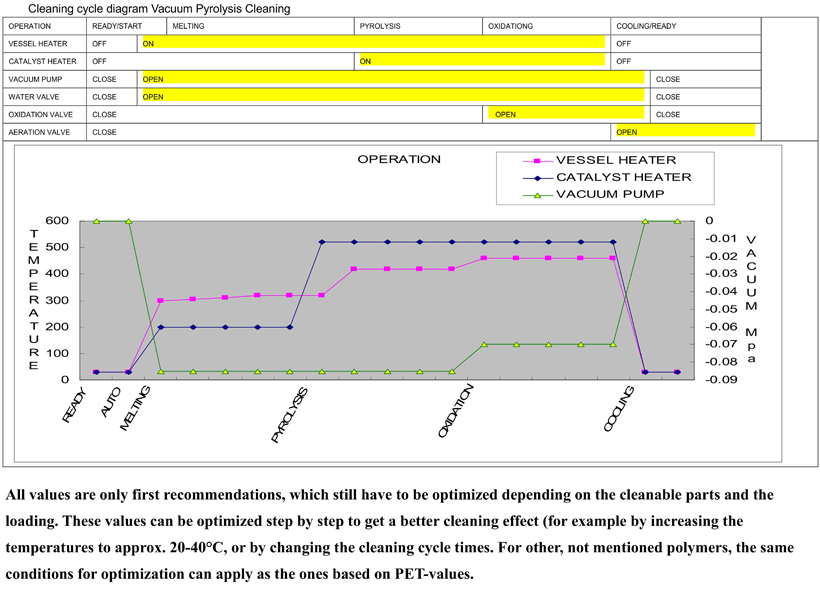

Vertical Vacuum Pyrolysis Cleaning Device: (VVPC-Series) Cleaning Objects:Filter of PET,PBT,PA,R-PET,Spin-pack of PSF As well as larger circular workpiece Cleaning Objects     Principle: Vacuum Pyrolysis Cleaning device is designed specially for cleaning polymers from a variety of metal components. The parts to be cleaned are heated in a chamber where the polymer melts and drains into the bottom collector. Remaining polymer is vaporized and then water scrubbed in a secondary scrubber where condensates are collected and rush out with water. Since cleaning takes place under vacuum, combustion does not occur. The parts are protected from excessive or localized high temperatures. The whole process has no pollution. Cleaning stage: A.Melting stage During heating up(150℃),the PET materials adhering to the spin packs(or Filter) to be cleaned first all become liquid but do not decompose thermally. The melting plastic flows via a discharge trough into the cooler melt container,where it can cool down and then be removed for the further porcessing stage. B.Pyrolysis stage On reaching the decomposition temperature of the respective polymer,the heat output is regulated automatically in the process chamber in such a way that the best possible conversion is guaranteed in the catalytic converter. C.Oxidation stage The oxygen is added to the process chamber to oxidise any remaining residues of the organic products of decomposition.Any remaining inorganic residues on the cleaned components can easily be removed mechanically, D.Cooling stage The process chamber heating is switched off during the cooling stage。 Main Parts: Vacuum cleaning furnace by vacuum furnace, furnace cover mechanism, loading rack operation mechanism, stainless steel electric heating tube, waste collection device, gas heating, water spray cleaning device, water ring vacuum pump, gas-water separator and a microcomputer program system, water, gas path, etc. Photo Of Device:   Specifications:

Advantage: Vacuum pyrolysis cleaning device can not only be used for cleaning various types of spinneret; also widely used in components, shell, metering pump cleaning. And it can also be specialized cleaning the filter which the TEG cleaning cannot be done. Fully reflects its excellent cleaning results, low operating costs, and easy to operate, safety, environmental protection and other advantages. Features and Advantages of New Vacuum Pyrolysis Cleaning Furnaces: 1、Better cleaning effect: can clean varies type of spinneret such as filament, staple fiber, profiled hole, superfine denier, composite spinning and so on, and also clean the component and shell as well. All can meet the user’s cleaning requirements, to achieve a very good cleaning effect. Some customers use vacuum pyrolysis cleaning furnace instead of TEG cleaning and fluidized bed furnace. 2、Low operating costs: only consume water and electricity without any other high-cost materials. After the vacuum cleaning, the spinneret can be cleaned only by ultrasonic cleaner. Workers operating strength is very low. 3、Better environmental performance: exhaust treatment equipment . A vacuum cleaning furnace with solid waste 70% - 80% without treatment, the remaining 20% were oxidized to form carbon dioxide and water vapor which itself environment is very good. Besides, a small amount of flue gas generated by the process passes through the tail gas treatment device. Further treatment,flue gas to be oxidation into carbon dioxide and water vapor, so that the environment is more clean. 4、Safe and reliable: using Siemens PLC to manage the equipment according to the program, not only high reliability, And has the following functions: ① Low water pressure alarm: to prevent water shortage cause the damage of vacuum pumps. ② Low vacuum alarm: to prevent the furnace body or seal leakage cause poor cleaning results. ③ Over-temperature alarm: When the furnace overheating occurs for whatever reason, the heating will be stopped in order, open the deflated valve to deflate, the pump shut down after delay to ensure that the equipment and the workpiece is not burned out. 5、Programmable control instruments: to ensure that the furnace temperature curve heating, to prevent the local part of the workpiece heating too fast; can make the workpiece within the furnace evenly heated to ensure the safety of the cleaning workpiece. 6、Multi-step furnace heating curve process: to ensure the reliable process of the flow of material in the furnace phase, the degradation stage, the oxidation stage, and guarantee a good cleaning effect. 7、The key components of the equipment, such as furnace lid, furnace, exhaust gas treatment device, gas scrubbing tower are made of stainless steel. 8、Vacuum pyrolysis furnace key technology - Vacuum Seal: we use a special high-temperature sealing material, can guarantee a good and durable high-temperature sealing, which is our company a major advantage. Photo Of Device:   | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||