| ||||||||||||||||||||||||||||||||||||||||||||||||

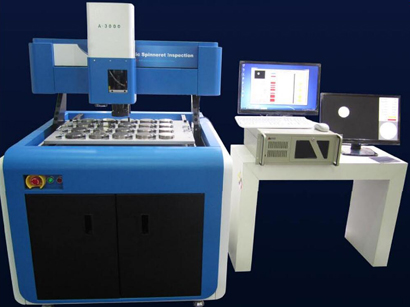

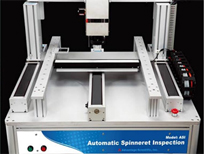

Automatic Spinnerette Inspection System ASI-6050 Series | ||||||||||||||||||||||||||||||||||||||||||||||||

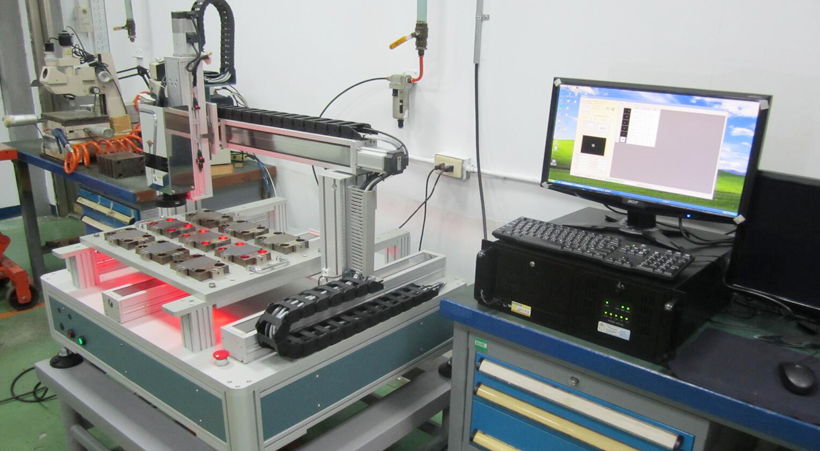

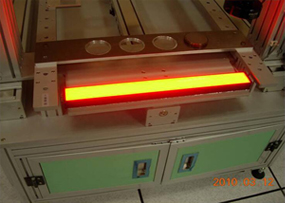

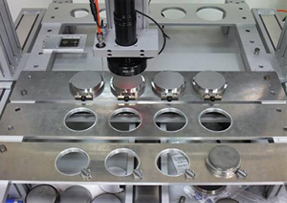

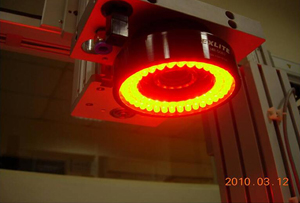

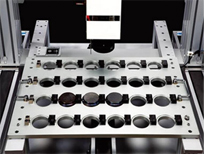

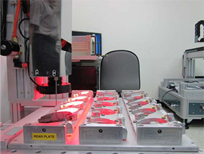

Inspection Objects: Spinnerette Spinnerette  The shape of detected hole  Principle: Automatic Spinnerette Inspection System, we has adopted the most advanced optical image processing techniques, applied sophisticated semiconductor optical equipment in combination with Japanese ultra-high precision screws, servo motors and imported high-resolution optical components with English versions of the operating software to develop an "Automatic Spinneret Detection,Cleaning and Imprint System" to assist enterprises in solving the previously mentioned spinning processing problems. Benefits:  1. Save labor cost; 2. Improve product quality and avoid secondary product problems; 3. Used as factory-entry quality detection for new spinneret; 4.Determine the usage years and quality of old spinnerets; 5. Assess the yield rate of cleaning equipment; 6. Instantly assess and improve abnormal spinning process phenomena; 7. Recover equipment costs within a short time. Platform: Fully automatic X-Y-Z-axis control platform(standard detection table:600X500mm) Motor: 400W AC servo motor(10000 parse) CCD Camera: Imported optical components,standard 800,000pixels high-resolution CCD Light source: High-brightness LED ring upper light source High-brightness LED row-like lower light source specific for semiconductor The number of spinnerets: With large-size detection platform of 600*500mm,several to dozens of spinnerets can be fixed and detected simultaneously according to the spinneret outside diameter. Automatic cleaning function: Unqualified holes are detected and cleaned automatically using air purge Automatic imprinting function: Holes that cannot be cleaned by air purge are automatically imprinted for a repeat cleaning by the operator. Automatic correction function: The system instrument self-corrects before detection in order to realize the most accurate measurement.     Configuration    Other Model   Main parts     Take Model ASI-6050F as sample for details: §1. Technical Parameters

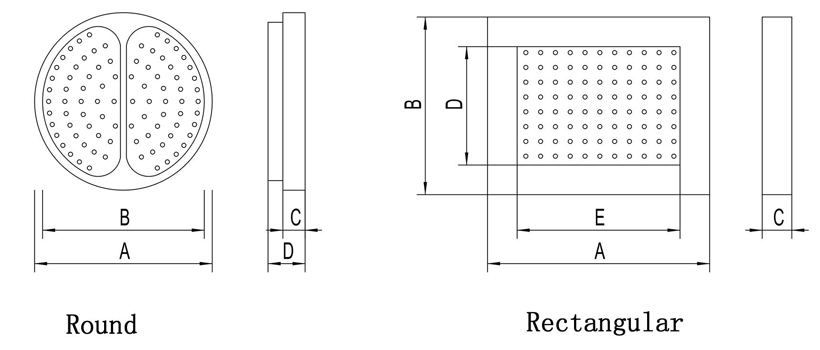

1. Profession "automatic spinneret detection, cleaning system" manufacturers, products cost-effective. 2. All-in-One floor-type machine, equipment stability is better than the average desktop type, and the machine has a spinneret fixture cabinet, saving fixture space. 3. Using a special large disk surface as spinneret home, can be placed multi piece of spinneret at same time. 4. Using imported high precision stepper motor and high definition lens group, with the latest image detection technology, rapid detection speed ( 0.5 ~ 1.2 seconds per hole, depending on the arrangement of spinning hole), better than traditional way of 1.25 seconds per hole. For ultra-porous number of spinneret, there is great economic benefits. 5. Using high brightness, high heat dissipation flat LED light source, does not need fan cooling. 6. Consummate pre-sale and after-sales service, at any time to answer customer consultation early stage of the cooperation , cooperation in the late stage of technical support for all kinds of difficult problems. 7. With remote maintenance function and can remote control the machine, to repair the machine any time. §3. Other Instructions  Please provide the data of the spinnerets Type of Spinnerets: 1.Round 2.Rectangular

|