| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cleaning Technology Solution For Spandex Fibre Project | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

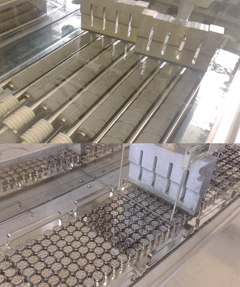

§ Cleaning Process A. Filter Cleaning Process 1. DMAC soaking Tank 2. Vacuum Pyrolysis Cleaning 3. High Pressure Washer 4. Ultrasonic Cleaning 5. Spinneret Inspection B. Spinneret Cleaning Process 1. DMAC soaking Tank 2. Vacuum Pyrolysis Cleaning 3. Ultrasonic Cleaning 4. Spinneret Inspection § Introduce  1. DMAC soaking Tank Put the filter or spinneret into the DMAC soaking tank for 12 hours, soak temperature about 130 degrees. Most of the melt has been cleaned.  2. Vacuum Pyrolysis Cleaning Vacuum Pyrolysis Cleaning device is designed specially for cleaning polymers from a variety of metal components. The parts to be cleaned are heated in a chamber where the polymer melts and drains into the bottom collector. Remaining polymer is vaporized.  3. High Pressure Washing High-pressure cleaning machine is used to remove Tio2 and alkali remaining in the filter core. Fully automatic process with programmable microprocessor controller for cleaning of single filter elements.Systems available for various filter candle dimensions and variable systems for different candle dimensions.  4. Ultrasonic Cleaning After high-pressure cleaning, ultrasonic cleaning follows to further remove remaining for fully clean, then bubbling inspection is used.  5. Bubble Point Testing The filter is submerged to a predetermined depth in the test liquid; air is introduced into the core of the filter with the pressure gradually increasing. The test liquid pushes through the filtering medium surface at a position on the filter body in line with the largest pore size or notable hole. The pressure at which air bubbles are emitted from the surface relates directly to the bubble-point pressure.  6. Spinneret Inspection Because spinneret hole cleaning is the key factor in spinning quality and efficiency, it is critically important to detect the cleanliness of spinneret holes. 1. Filter Cleaning

|